PTFE Compound

Overview of fluoroplastic (PTFE) compound

High functionality compound material Fluoroplastic compound

Using fluoroplastic as base, we propose compound material with fillers according to your application.

Fluoroplastic compound molded products demonstrate excellent chemical resistance, thermal resistance, electrical properties and remarkably low coefficient of friction. However, for imparting more mechanical strength according to the application, they are used after mixing with various fillers.

According to your desired properties, we will present the most appropriate types of filler and blending amount.

Types and features of fillers

We offer the following varieties of fillers according to diverse applications.

| Filler | Features and size | Expected functions |

|---|---|---|

| Glass fiber | Milled fiber of grain diameter 10-15μm | Wear resistance |

| Carbon | Amorphous carbon of grain diameter 75μm or below | Wear resistance, cold flow resistance, compression characteristics |

| Graphite | Crystalline carbon of grain diameter 40-50μm | Sliding characteristics, water resistance |

| Bronze | Spherical powder of grain diameter 40μm or below | Cold flow resistance, hardness, compression characteristics |

| Molybdenum disulfide | Spherical powder of grain diameter 40μm or below | Lubricating property, sliding characteristics |

| Carbon fiber | Filled fiber of diameter 8-10μm | Cold flow resistance, compression characteristic, electrical conductivity |

| Various engineering plastics | PPS, PEEK, Econol, polyimide, etc. | Cold flow resistance, compression characteristics, passive against sliding material |

Main properties of PTFE compound

| Item | Unit/Measurement conditions |

Glass Fiber 15% |

Glass Fiber 25% |

Carbon 15% |

Bronze 60% |

Glass Fiber 20% Carbon 5% |

Glass Fiber 15% MoS2 5% |

Carbon Fiber 15% |

|---|---|---|---|---|---|---|---|---|

| Specific gravity | – | 2.2 | 2.23 | 2.13 | 3.7 | 2.22 | 2.23 | 2.04 |

| Tensile Strength | MPa(JIS K6891) ⊥ | 25 | 20 | 19 | 17 | 22 | 22 | 20 |

| Elongation | %(JIS K6891) ⊥ | 300 | 260 | 270 | 200 | 270 | 280 | 280 |

| Compressive strength | MPa(1% deformation 24℃) || | 7.5 | 8.5 | 7.5 | 10.4 | 9 | 7.8 | 8.5 |

| Compressive creep | %(2000psi,24hrs,24℃) || | 8.8 | 7.9 | 5.6 | 3.1 | 4.4 | 5.6 | 3.3 |

| Hardness | Durometer D(24℃) | 60 | 63 | 62 | 70 | 61 | 60 | 60 |

| Coefficient of friction |

Static friction static2kg/cm2 Kinetic friction kinetic2kg/cm2 50m/min. |

0.05 0.10 |

0.07 0.12 |

0.05 0.10 |

0.08 0.12 |

0.07 0.10 |

0.04 0.07 | 0.15 |

| Wear coefficient | mm/km/MPa X 10-6 | 1.2 | 1 | 6.7 | 0.7 | 0.5 | 1 | 1 |

| Thermal conductivity | Kcal/m/hr/℃ | 0.29 | 0.34 | 0.34 | 0.42 | 0.32 | 0.28 | 0.4 |

||:Direction of applying pressure ⊥:Perpendicular direction of applying pressure

For compositions other than the above, we can customize according to your requirements.

Features of processing

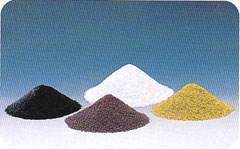

Powder and Granules PTFE compound for various molding.

- Top Page

- Compound

- Fluoro Sponge

- Fluoro Sponge, Compound Sheet

- Fluororesin Compound

- PTFE Compound

- MF Pellet

- MFP-CMB45L

- MFP-CLLAR

- MFP-TP

- MFP-RB

- MFP-TiL

- FKM Compound

- Bubbles

- Backing material for flooring

- Milled Products

- Waterproofing of Veranda

- Civil engineering masonry joint

- Cosmetic Goods

- Other

- Packaging Material

- Sports Goods

- Toys

- Signboard Industry

- Development Facilities

- Company Profile