MFP-CLLAR

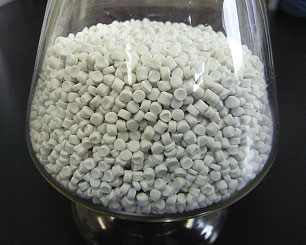

MFP-CLLAR is a masterbatch prepared filling 80% calcium carbonate in L-LDPE (plastic).

Features of MFP-CLLAR

- Does not result in the loss of physical properties even when used as bulking agent.

- When used in films, it improves printing properties and adhesive properties.

Example of Applications of MFP-CLLAR

- Can be used as bulking agent.

- Garbage bag (white), plastic shopping bag

- OA floor

- Bleed retardant

- PP band

Basic Physical Properties of MFP-CLLAR

| MFP-CLLAR | |||

|---|---|---|---|

| Specific gravity | Water displacement method | – | 1.92 |

| MFR | 190℃-10kg | g/10min | 15 |

| Moisture content | Karl Fischer 180℃ | ppm | 240 |

* Figures shown here are indicative values and not guaranteed values.

Precautions while using MFP-CLLAR

- MFP-CLLAR is of hygroscopic nature. Although aluminum inner bag is used in packaging as moisture proof bag, pay adequate attention to humidity of the storage place.

- When bubble formation is seen in the molded articles, there is a possibility of moisture absorption. Use after adequate drying. When moisture exceeds 400 ppm, possibility of bubble formation becomes high.

- If the resin temperature is high, “Eye Mucus” may generate. In this case, reduce the resin temperature and adjust it to suitable level.

Changes in MFP-CLLAR moisture over time

![[Graph] MFP-CLLAR moisture overtime](/en/images/compound/mfp-cllar_graph.gif)

Changes in Properties when MFP-CLLAR is added to TPV

| Test items | Test conditions | Other company TPV HS70 | TPV (HS70) CLLAR 90/10 | TPV(HS70) CLLAR 70/30 | Other company TPV HS80 | ||||

|---|---|---|---|---|---|---|---|---|---|

| Basic Properties | Specific gravity | Water displacement method | – | 0.88 | 0.93 | 1.04 | 0.89 | ||

| Hardness | Instant value | – | 70 | 73 | 79 | 87 | |||

| Durometer A | After 9 seconds | – | 64 | 68 | 73 | 83 | |||

| MFR | 230℃-2.16kg | g/10min | 0.03 | 0.3 | 0.3 | Does not flow | |||

| 230℃-10.0kg | g/10min | 41 | 54 | 67 | 15 | ||||

| Mechanical Properties | 100% modulus | No. 3 dumbbell | MPa | 2.1 | 2.2 | 2.2 | 3.8 | ||

| Tensile yield point stress | Stretching speed: | MPa | 4.2 | 5.7 | 5.7 | 6.7 | |||

| Elongation after tensile rupture | 200mm/min | % | 390 | 590 | 640 | 410 | |||

| Permanent compression set | 70℃-22h | % | 37 | 47 | 49 | 57 | |||

| Machining | Garvey die | Edge A(Good)⇔E(Poor) | – | B | B | B | B | ||

| Swell A(Small)⇔E(Large) | – | A | A | A | C | ||||

| Bubble formation | – | No | No | No | No | ||||

| Article | Checked with 0.5 mm sheet | No./g | 0 | 0 | 0 | 0 | |||

* Figures shown here are indicative values and not guaranteed values.

- Top Page

- Compound

- Fluoro Sponge

- Fluoro Sponge, Compound Sheet

- Fluororesin Compound

- PTFE Compound

- MF Pellet

- MFP-CMB45L

- MFP-CLLAR

- MFP-TP

- MFP-RB

- MFP-TiL

- FKM Compound

- Bubbles

- Backing material for flooring

- Milled Products

- Waterproofing of Veranda

- Civil engineering masonry joint

- Cosmetic Goods

- Other

- Packaging Material

- Sports Goods

- Toys

- Signboard Industry

- Development Facilities

- Company Profile