MFP-TP

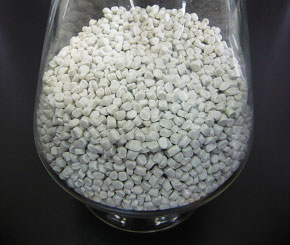

MFP-TP is a masterbatch prepared by filling 80% talc in PP (plastic).

Features of MFP-TP

- If can increase the stiffness of the molded items.

- It reduces shrinkage factor, because of which there would be lesser shrinkage and cavity, which would increase dimensional stability.

- Because of higher heat distortion temperature, it improves heat resistance.

- It improves properties such as increase in bending elasticity and bending strength, and shorter molding cycle.

Examples of Application of MFP-TP

- Hangers

- Automobile parts

- In home appliance parts

- Pellets, etc.

Basic Properties of MFP-TP

| MFP-TP20 | MFP-TP25 | MFP-DT41 | MFP-TP40 | MFP-TP45 | |||

|---|---|---|---|---|---|---|---|

| Specific gravity | Water displacement method | – | 1.92 | 1.92 | 1.68 | 1.92 | 1.92 |

| MFR | 190℃-10㎏ | g/10min | 25 | 25 | 30 | 25 | – |

| Moisture | Karl Fischer 180℃ | ppm | 450 | 450 | 400 | 500 | – |

| Whiteness | Whiteness of talc raw material | 90 | 90 | 95 | 90 | 80 | |

| Examples of application | Automobile parts | Hanger | Automobile parts | Sheet for foodstuff | Pellet | ||

* Figures shown here are indicative values and not guaranteed values.

Property Values when Talc MB is added to PP

Test specimens are prepared with injection molding

Charpy impact test: Notch is cut after injection molding test preparation. Home PP is hammer 2J and block PP is hammer 7.5J.

Home PP : Prime polymer J108M

Block PP: Prime polymer J466HP

| Test Items | Test Conditions | Unit | 4μm talc | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Homo PP/DT41 | |||||||||

| Talc concentration (wt%) | |||||||||

| 0 | 10 | 20 | 30 | 40 | |||||

| Specific gravity | Water displacement method | - | 0.91 | 0.96 | 1.04 | 1.13 | 1.23 | ||

| Melt flow rate | 230℃-2.16kg | g/10min | 47 | 52 | 55 | 57 | 58 | ||

| Tensile yield point stress |

Temperature 23℃ Speed 20mm/min Test specimen JISK7319A type | MPa | 35 | 35 | 34 | 33 | 29 | ||

| Elongation after tensile rupture | % | 14 | 7 | 6 | 5 | 2.7 | |||

| Bending elastic modulus |

Temperature 23℃ Speed 2mm/min Span width 64mm, Test specimen ISO3167 Taken from center | MPa | 2050 | 2700 | 3700 | 4550 | 5750 | ||

| Bending strength | MPa | 52 | 55 | 60 | 58 | 56 | |||

| Charpy impact test | With notch, temperature 23℃ | kJ/m2 | 1.2 | 1.1 | 1.2 | 1.2 | 1.3 | ||

| Deflection temperature under load | 0.45MPa Flat-wise test | ℃ | 105 | 119 | 121 | 127 | 132 | ||

| Molding shrinkage ratio |

Test board 120×150×t3mm N=10 48 hours after molding (23℃) | Vertical | % | - | - | - | - | - | |

| Horizontal | - | - | - | - | - | ||||

* Figures shown here are indicative values and not guaranteed values.

| Test Items | Test Conditions | Unit | 4μm talc | |||||

|---|---|---|---|---|---|---|---|---|

| Block PP/DT41 | ||||||||

| Talc concentration (wt%) | ||||||||

| 0 | 10 | 20 | 30 | 40 | ||||

| Specific gravity | Water displacement method | - | 0.9 | 0.96 | 1.04 | 1.13 | 1.23 | |

| Melt flow rate | 230℃-2.16kg | g/10min | 3 | 3.8 | 4.7 | 7 | 9 | |

| Tensile yield point stress |

Temperature 23℃ Speed 20mm/min Test specimen JISK7319A type | MPa | 20 | 21 | 22 | 22 | 24 | |

| Elongation after tensile rupture | % | 50 or less | - | - | - | 10 | ||

| Bending elastic modulus |

Temperature 23℃ Speed 2mm/min Span width 64mm, Test specimen ISO3167 Taken from center | MPa | 990 | 1570 | 2250 | 3300 | 4400 | |

| Bending strength | MPa | 27 | 32 | 36 | 39 | 41 | ||

| Charpy impact test | With notch, temperature 23℃ | kJ/m2 | 54 | 30 | 11 | 5 | 3 | |

| Deflection temperature under load | 0.45MPa Flat-wise test | ℃ | 79 | 91 | 101 | 110 | 118 | |

| Molding shrinkage ratio |

Test board 120×150×t3mm N=10 48 hours after molding (23℃) | Vertical | % | 1.522 | - | 1.02 | - | - |

| Horizontal | 1.467 | - | 0.952 | - | - | |||

* Figures shown here are indicative values and not guaranteed values.

| Test Items | Test Conditions | Unit | 19μm talc | |||||

|---|---|---|---|---|---|---|---|---|

| Homo PP/TP20 | ||||||||

| Talc concentration (wt%) | ||||||||

| 0 | 10 | 20 | 30 | 40 | ||||

| Specific gravity | Water displacement method | - | 0.91 | 0.96 | 1.04 | 1.13 | 1.23 | |

| Melt flow rate | 230℃-2.16kg | g/10min | 47 | 50 | 51 | 51 | 52 | |

| Tensile yield point stress |

Temperature 23℃ Speed 20mm/min Test specimen JISK7319A type | MPa | 35 | 34 | 33 | 32 | 29 | |

| Elongation after tensile rupture | % | 14 | 13 | 11 | 7 | 4 | ||

| Bending elastic modulus |

Temperature 23℃ Speed 2mm/min Span width 64mm, Test specimen ISO3167 Taken from center | MPa | 2050 | 2650 | 3320 | 4130 | 5080 | |

| Bending strength | MPa | 52 | 54 | 54 | 54 | 52 | ||

| Charpy impact test | With notch, temperature 23℃ | kJ/m2 | 1.2 | 1.5 | 1.7 | 1.4 | 1.4 | |

| Deflection temperature under load | 0.45MPa Flat-wise test | ℃ | 105 | 119 | 120 | 126 | 131 | |

| Molding shrinkage ratio |

Test board 120×150×t3mm N=10 48 hours after molding (23℃) | Vertical | % | - | - | - | - | - |

| Horizontal | - | - | - | - | - | |||

* Figures shown here are indicative values and not guaranteed values.

- Top Page

- Compound

- Fluoro Sponge

- Fluoro Sponge, Compound Sheet

- Fluororesin Compound

- PTFE Compound

- MF Pellet

- MFP-CMB45L

- MFP-CLLAR

- MFP-TP

- MFP-RB

- MFP-TiL

- FKM Compound

- Bubbles

- Backing material for flooring

- Milled Products

- Waterproofing of Veranda

- Civil engineering masonry joint

- Cosmetic Goods

- Other

- Packaging Material

- Sports Goods

- Toys

- Signboard Industry

- Development Facilities

- Company Profile