Fluoro Rubber Independent Bubble Sponge

The DF700 series, MF-20S, and AF-150 are sponges with an independent bubble structure that take advantage of the features of fluorocarbon rubber (FKM), which is heat resistant, chemical resistant, solvent resistant, and has low outgassing. Customers can choose from nine types of sponges with different hardness and foam magnification to suit their needs.

Table of Contents

- What are Independent Bubbles?

- Heat, chemical, oil, and solvent resistant sponge

- Low outgassing sponge

- Sponge with flame retardant properties

- Application Examples

- Grade List [Catalog Download] (Japanese only)

- Product Sizes/Processing Methods

- Environmental Survey Response

- Samples/Inquiries

1. What are independent bubbles?

There are two main types of sponges: those that allow water to pass through and those that do not.

As the name implies, independent bubbles are sponges with independent bubbles that do not allow water to pass through, like a bead board.

On the other hand, a sponge with connected air bubbles is called a continuous bubble sponge, and dishwashing sponges are well known for this. Click here to see the fluorine rubber continuous bubble sponge.

2. heat, chemical, oil, and solvent resistant sponge

The DF700 series, MF-20S, and AF-150 are fluororubber sponges that take advantage of the features of fluororubber to resist heat up to 230°C and are very good for chemicals such as benzene, toluene, xylene, and fuel oil such as FuelC.

3. low outgassing sponge

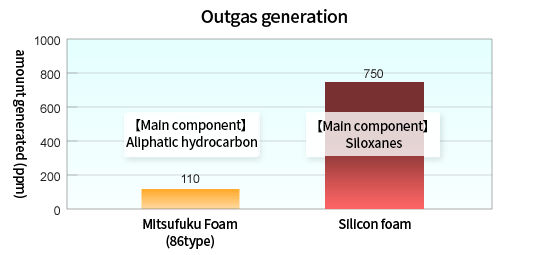

Our fluoroelastomer sponges do not contain siloxanes and emit much less than silicone sponges.

Our unique compounding design and processing method reduces outgassing during use, making it possible to use the sponge in environments where outgassing is not desired, such as semiconductors.

It contains no siloxanes and generates far less than silicone!

| Measuring device | Purge & Trap - Gas Chromatogram Mass Spectrometer (P&T-GC/MS) |

|---|---|

| Heating conditions | 200°C×15min |

| Purge gas | He(50ml/min) |

| Reference materials | Decane |

4. flame retardant sponge

Our fluoroelastomer sponge is V-0 equivalent level in the test based on UL94V judgment.

Combustion characteristics

| Sample name | UL94V rating |

| 1. DF700 | *V-0 |

| 2. DF700S-86 | V-0 |

| 3. DF-900 | V-0 |

| Sample size | 125mm x 13mm |

| Test conditions | Test based on UL94V combustion test method |

| Sample donditioning | Left at 23°C, 50% relative temperature for at least 48 hours |

[Testing organization] Analysis and Evaluation Department, Kita-Kanto Center, Sumibe Tsutsuzunaka Techno Co.

5. Example Applications

It is used in the field of semiconductors, where outgassing is minimal and a siloxane-free environment is preferred.

It is also used in various fields as cushioning material for hot presses, packing, and gaskets, taking advantage of its heat resistance and solvent resistance.

- Packing for semiconductor manufacturing equipment

- Industrial packing, gaskets, etc.

- Use in clean rooms

- Hot press cushioning material 【Hot press cushioning material MF-20S】

6. List of our product grades [Catalog Download]

Fluoro Rubber Foam Grade List Properties

A = Very good / B = Good / C = Normal

| Test item, unit, condition \ Product name | DF700S-86 | DF-700 | DF900 | DF700-37HS | DF700-55HS | AF-150 | MF-20S | ||

|---|---|---|---|---|---|---|---|---|---|

| Apparent density | kg/m3 | 240 | 270 | 470 | 390 | 1030 | 270 | 590 | |

| 100% Modulus | MPa | 0.34 | 0.94 | 0.65 | 1.28 | 2.45 | 0.18 | 0.65 | |

| Tensile strength | MPa | 0.86 | 1.24 | 1.19 | 1.76 | 4.48 | 1.47 | 2.00 | |

| Elongation at break | % | 160 | 120 | 410 | 130 | 170 | 530 | 200 | |

| Compressive Stress-Strain | 10% | 0.01 | 0.03 | 0.06 | 0.06 | 0.23 | 0.01 | 0.06 | |

| (MPa) | 25% | 0.03 | 0.08 | 0.09 | 0.12 | 0.51 | 0.03 | 0.13 | |

| 50% | 0.08 | 0.14 | 0.20 | 0.28 | 1.65 | 0.20 | 0.27 | ||

| Compression set (%) | Normal temp x 24h | 3 | 6 | 24 | 1.3 | 0.84 | - | - | |

| 150°C x 24h | 109 | 81 | 121 | 66 | 26 | 142 | 12.5 | ||

| 180°C x 24h | 140 | 101 | 143 | 86 | 39 | 157 | 24 | ||

| 200°C x 24h | 155 | 119 | 145 | 106 | 55 | 175 | 49 | ||

| Hardness | Atype | 6 | 12 | 21 | 22 | 48 | 7 | 22 | |

| Ctype | 15 | 26 | 40 | 36 | 66 | 13 | 38 | ||

| Solvent immersion test (Normal temp x 72 hours) | Benzene | B | – | A | B | – | C | A | |

| Toluene | B | – | A | B | – | C | A | ||

| Xylene | B | – | A | B | – | C | A | ||

| FuelC75%+ | C | – | A | B | – | C | A | ||

| Methanol 25% | |||||||||

| MAX size | mm | 800×1000 | 700×800 | 500×500 | 750×750 | 750×750 | 800×1000 | 600×650 | |

| MAX thickness | 10t | 6t | 6t | 9t | 6t | 10t | 10t | ||

*The values in the table are typical values, not standard values. Performance may vary depending on usage conditions.

*Right-click on the file and select "Save Target As/Save As" to download the file.

7. size/processing method

Size: We will cut to your desired size within the MAX size range.

Thickness: We can cut up to 0.5 mm by taking advantage of our unique slicing technology.

Product shape: Sheet shape by cutting and packing shape by secondary processing are available.

Various processing methods are available, such as attaching double-sided tape or polyimide film (*MITSUFUKU SHEET).

Order quantity:We accept orders from 1 piece/1 piece.

8. Environmental Survey Compliance

We can submit documents related to various environmental surveys such as RoHS, ChemSHERPA, SDS, etc.

9.Sample/Inquiries

We would be happy to provide you with products tailored to your application.

Please feel free to contact us through [Contact Us] on our website regarding inquiries about our products.