Fluoroplastic foam sheet

MF-Fluorosheet is a fluoroplastic foam sheet (fluoroplastic sponge) with heat resistance, non-adhesiveness, low dielectric constant and low dielectric loss tangent.

This product has an even lower dielectric constant than PTFE, which has an extremely low dielectric constant among plastics, and is expected to play an active role in high-frequency communication applications. We have a lineup of three types according to hardness to meet customers' applications.

Table of Contents

- Features of MF-Fluorosheet (general properties, thermal properties)

- Physical Properties

- Low dielectric constant and dissipation factor

- Surface condition observation

- Effects of chemicals

- Effects during heating

- Thermal conductivity

- Applications

- Product Size/Processing Method

- Environmental Survey Response

- Samples/Inquiries

1.MF-Fluorosheet Features

- 100% fluoropolymer impurity-free foam

Heat resistant, chemical resistant, non-adhesive, water repellent, chemical adsorption, breathable, low dielectric constant, etc. - Thickness, length, and shape can be adjusted according to the application, such as tubular or sheet form, and can be crushed by tightening and compressing

Insulation cover, filtration sheet (oil-water separation membrane), gasket (when tightened) - Due to the different structure from stretched sheets, there is less expansion and contraction due to heat, which reduces problems during installation and use when used as gaskets, etc.

| Entry | PTFE | MF-60P | MF-70P | MF-75P | Test conditions |

|---|---|---|---|---|---|

| Hardness | 80 | 72 | 52 | 39 | Durometer A Peak value |

| 95 | 83 | 68 | 50 | Asker C | |

| Density[g/cm3] | 2.15 | 0.86 | 0.62 | 0.51 | |

| Tensile strength[MPa] | Unmeasured | 2.42 | 1.20 | 0.67 | JIS K 6251 |

| Growth[%] | Unmeasured | 81 | 71 | 59 | JIS K 6251 |

| Porosity[%] | 0 | 60 | 71 | 76 | (Fluoropolymer density - fluoropolymer foam density)/PTFE density x 100 |

| Amount of wear[mg] | Unmeasured | 142 | 261 | 1245 | JIS K 7204 |

| Load = 250g, Wear wheel = H-22, Number of revolutions = 1000, Rotational speed = 60rpm | |||||

| Breathability[sec/100ml] | Unmeasured | 3.8 | 1.3 | 0.6 | JIS P 8117 (Garre densometer) |

| Dielectric constant | Unmeasured | 1.37 | 1.27 | 1.22 | IPC TM-650 2.5.5.13 (Cavity resonator method) Frequency: 20GHz |

| Dielectric tangent | Unmeasured | 0.00021 | 0.00017 | 0.00016 |

| PTFE | MF-Fluorosheet [MF-75P] |

||

|---|---|---|---|

| Physical properties | Specific gravity | 2.15 | 0.49 |

| Thickness[mm] | 1.28 | 0.62 | |

| Specific heat capacity[J/g/K] | 1.125 | 1.822 | |

| Thermal diffusivity[mm2/s] | 0.108 | 0.061 | |

| Thermal conductivity[W/mK] | 0.261 | 0.054 |

Equipment used: Xe flash analyzer (NETZSCH)

Measuring conditions: Laser flash method at a set temperature of 25°C

2. Physical properties

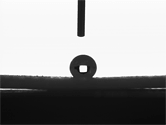

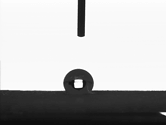

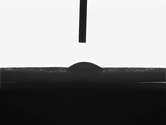

Table.1 Contact angle to water

| Elapsed time[ms] | C.A[°] | |

|---|---|---|

| PTFE | MF-75P | |

| 1000 | 76.7 | 103.8 |

| 3000 | 76.5 | 104.9 |

| 5000 | 76.7 | 103.8 |

| 7000 | 76.7 | 103.8 |

| 9000 | 76.5 | 103.8 |

Machine used : Contact angle meter DM-501 (Kyowa Chemical)

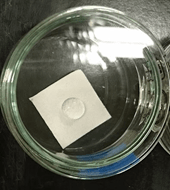

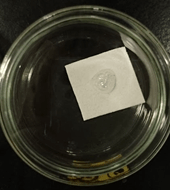

Figure.1 Contact angle to water (MF-75P)

-

1000ms -

5000ms -

9000ms

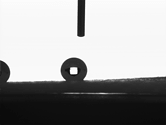

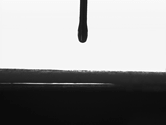

Table.2 Contact Angle to Ethanol

| Elapsed time[ms] | C.A[°] | |

|---|---|---|

| PTFE | MF-75P | |

| 1000 | 42.6 | 62.5 |

| 1500 | 42.3 | 49.3 |

| 3000 | 41 | 3.4 |

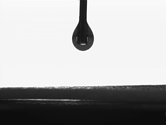

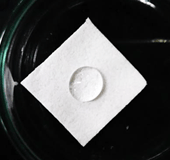

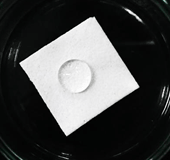

Figure.2 Contact angle to ethanol (MF-75P)

-

1000ms -

1500ms -

3000ms

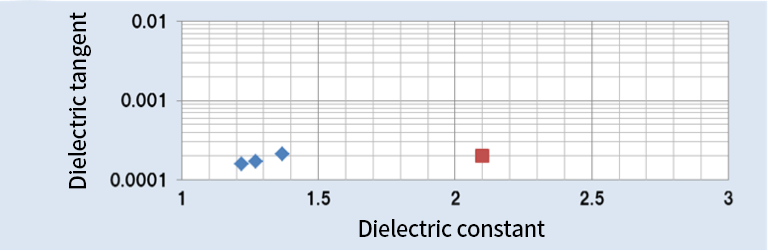

3. Low dielectric constant and low dielectric loss tangent

| Entry | Unit | Conditions | MF-60PS | MF-70PS | MF-75PS |

|---|---|---|---|---|---|

| Dielectric constant | - | Frequency 20GHz | 1.37 | 1.27 | 1.22 |

| Dielectric tangent | tanδ | Frequency 20GHz | 0.00021 | 0.00017 | 0.00016 |

For more information, click here to download the PDF.

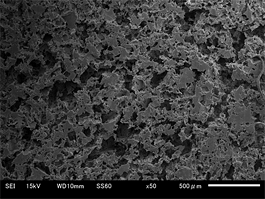

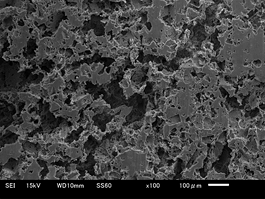

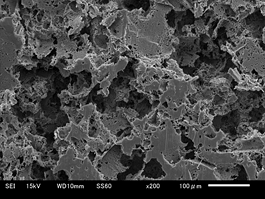

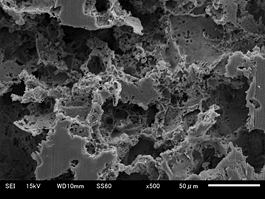

4. Surface condition observation

-

50 magnifications -

100 magnifications -

200 magnifications -

500 magnifications

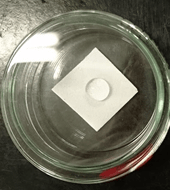

5. Effects of chemicals

1. Drop acid, alkali, or oil and observe the change in appearance

Chemicals used

- 0.1 mol/L Hydrochloric acid

- 0.1 mol/L sodium hydroxide solution

- Silicon oil

Immediately after dropping

-

Acid -

Alkali -

Oil

1 hour later

-

Acid -

Alkali -

Oil

No change in any of the above

⇒ No deterioration due to acid or alkali was observed.

2. Immersion in acid, alkali, and oil to investigate dimensional changes

Chemicals used

- 0.1 mol/L Hydrochloric acid

- 0.1 mol/L sodium hydroxide solution

- Silicon oil

Conditions

Room temperature 25°C, 72hour

-

Acid -

Alkali -

Oil

No dimensional change in any of the samples

No deterioration was observed

6. Effect on heating

Instrument used: GCMS-QP2010 (Shimadzu Corporation)

Measuring conditions : Thermal desorption method (DESP), 200°C

| PTFE | MF-75P | |

|---|---|---|

| Detected substance | None | None |

When heated at 200°C, none of the gases, etc. generated were observed.

7. Applications

It is expected to play an active role in the field of semiconductors, where outgassing is minimal and a siloxane-free environment is preferred.

Insulation covers, filtration sheets (oil-water separation membranes), gaskets (when tightened), etc.

8. product size/processing method

Size: We will cut to your desired size within the range of MAX size (20 mm thick) and provide it to you.

Product shape: Sheets, tubes and cylindrical shapes are also available. Ordering quantity: We accept orders from 1 sheet/1 piece.

9. Environmental Survey Compliance

We can submit documents related to various environmental surveys such as RoHS, ChemSHERPA, SDS, etc.

10.Sample/Inquiries

We would be happy to provide you with products tailored to your application.

Please feel free to contact us through [Contact Us] on our website regarding inquiries about our products.