Hot press buffer material MF-20S

MF-20S is a heat-resistant sponge with excellent compression set developed for heat presses.

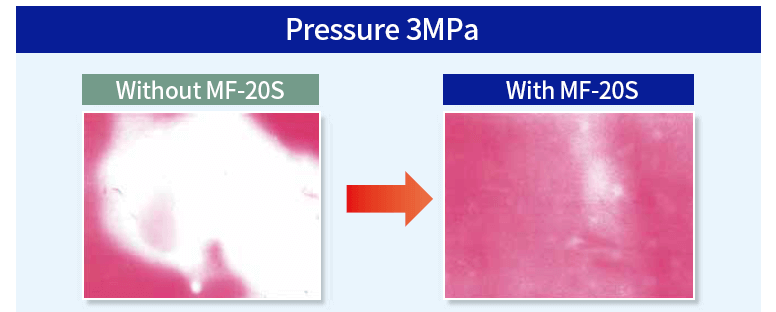

The advantage of sponges is that they distribute pressure evenly, which improves unevenness in press pressure, which in turn improves the defect rate.

Product yield improvement can be expected.

In addition, it improves compression set, which is a disadvantage of sponge, and can be used repeatedly (long-term life).

It is a product that also leads to cost reduction.

It can also be used as a packing or gasket by taking advantage of its excellent CS property.

Table of Contents

- Demerits of Conventional Press Cushioning Materials

- MF-20S Compression Set (CS Value) Data

- List of our product grades

- Sizes/Product Shapes/Order Quantities

- Environmental surveys, etc.

- Samples/Inquiries

1. demerits of conventional pressed cushioning materials

- Paper, film, and non-woven fabrics are one-way materials, and there are problems with inventory space and waste.

- Rubber and sponge are not resistant to heat and deteriorate.

- They are not heat resistant and deteriorate quickly, making them unusable.

- Gases are generated during pressing, contaminating the object and the press.

- Since the surface pressure is not constant, the press is pressed at high pressure, damaging the press machine. etc.

By using MF-20S, the above disadvantages can be solved.

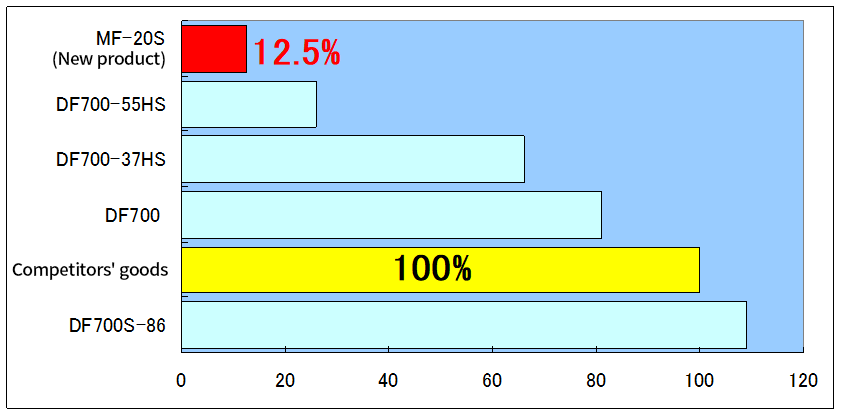

2. compression set (CS value) data

MF-20S has the best compression set value among our fluorine sponges, especially in heat resistance.

compression set

It is an indicator of whether a rubber, resin, sponge, etc. will remain deformed (distorted) and not recover/restore when it is compressed and then released. For a simple example, a chest of drawers or a desk is placed on a tatami mat, and after a long period of time, the tatami mat is dented. This is an index to measure the state of deformation and non-restoration under pressure like this.

A CS value of 0% is a fully restored state.

3. List of our product grades

| Test item, unit, condition \ Product name | DF700S -86 |

DF-700 | DF900 | DF700 -37HS |

DF700 -55HS |

AF-150 | MF-20S | ||

|---|---|---|---|---|---|---|---|---|---|

| Apparent density | kg/m3 | 240 | 270 | 470 | 390 | 1030 | 270 | 590 | |

| 100% Modulus | MPa | 0.34 | 0.94 | 0.65 | 1.28 | 2.45 | 0.18 | 0.65 | |

| tensile strength | MPa | 0.86 | 1.24 | 1.19 | 1.76 | 4.48 | 1.47 | 2.00 | |

| Elongation at break | % | 160 | 120 | 410 | 130 | 170 | 530 | 200 | |

| compressive stress -strain |

10% | 0.01 | 0.03 | 0.06 | 0.06 | 0.23 | 0.01 | 0.06 | |

| (MPa) | 25% | 0.03 | 0.08 | 0.09 | 0.12 | 0.51 | 0.03 | 0.13 | |

| 50% | 0.08 | 0.14 | 0.20 | 0.28 | 1.65 | 0.20 | 0.27 | ||

| Compression set (%) | Normal Temp x 24h | 3 | 6 | 24 | 1.3 | 0.84 | - | - | |

| 150°C × 24h | 109 | 81 | 121 | 66 | 26 | 142 | 12.5 | ||

| 180°C × 24h | 140 | 101 | 143 | 86 | 39 | 157 | 24 | ||

| 200°C × 24h | 155 | 119 | 145 | 106 | 55 | 175 | 49 | ||

| hardness | Atype | 6 | 12 | 21 | 22 | 48 | 7 | 22 | |

| Ctype | 15 | 26 | 40 | 36 | 66 | 13 | 38 | ||

| Solvent immersion test (Normal Temp x 72h) |

benzene | B | – | A | B | – | C | A | |

| toluene | B | – | A | B | – | C | A | ||

| xylene | B | – | A | B | – | C | A | ||

| FuelC75%+ | C | – | A | B | – | C | A | ||

| methanol25% | |||||||||

| MAX size | mm | 800×1000 | 700×800 | 500×500 | 750×750 | 750×750 | 800×1000 | 600×650 | |

| MAX thickness | 10t | 6t | 6t | 9t | 6t | 10t | 10t | ||

*The values in the table are typical values, not standard values. Performance may vary depending on usage conditions.

*Right-click on the file and select "Save Target As/Save As" to download the file.

4. size/processing method

Size

We will cut to your desired size within the MAX size range.

Thickness can be up to 0.5 mm by taking advantage of our unique slicing technology.

Product Shape

Sheet shape by cutting and packing shape by secondary processing are available.

We also offer a variety of processing methods, such as attaching double-sided tape or polyimide film (*MITSUFUKU SHEET).

Order quantity

We accept orders from 1 piece/1 piece.

5. Environmental Survey Compliance

We can submit documents related to various environmental surveys such as RoHS, ChemSHERPA, SDS, etc.

6. Sample/Inquiries

We would be happy to provide you with products tailored to your application.

Please feel free to contact us through [Contact Us] on our website regarding inquiries about our product